Temporary Vertical Concrete Barriers

Cast from our highly regarded high strength concrete (50N/mm2) and combined with National Highways specification steel reinforcing, means that the barriers meet the component requirements of EN 1317 ‘Compliant Road Restraint Systems for Temporary Safety Barriers’ (when installed by a Highways Agency approved contractor).

TVCBs can be used for various applications, including:

- Flood defence walls

- Temporary works

- Vehicle security barriers (VSBs)

- Vehicle containment barriers (VCBs)

- Hostile Vehicle Mitigation (HVM)

- Preventing unauthorised access and trespassing

- Deterring fly-tipping

- Managing and guiding traffic during road construction

- Crowd control at public events and times, such as COVID

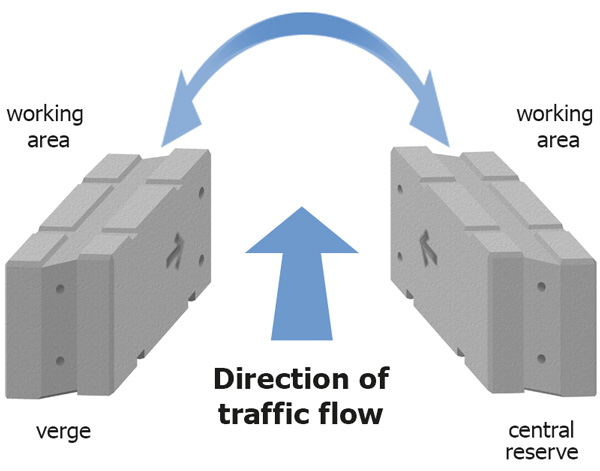

- Creating a safe working area for you workforce

- Protecting pedestrians

- As counterweights, kentledge for scaffolding, fencing, cranes etc

- Providing security against ram raiders and terrorist attacks

Benefits of temporary vertical concrete barriers (TVCBs)

Enhanced safety

TVCBs provide robust protection on roads and public events, significantly reducing the risk of severe injuries and fatalities by preventing vehicles from straying onto oncoming traffic or pedestrian areas.

Durability

These barriers can withstand harsh weather and heavy impacts without major damage, maintaining their protective nature over time.

Deployment

TVCB barriers are easy to transport and deploy quickly, making them ideal for temporary events.

Cost-effectiveness

When compared to permanent security structures, TVCBs offer a cost-effective solution for temporary events and short-term security needs.

High-speed protection

TVCBs are designed to deflect errant vehicles traveling along the roads, providing protection for road workers and users

Flexibility

The modular nature of TVCBs allows for quick assembly and disassembly, enabling companies to adapt the security layout as required.

Compliance

Vertical barriers and blocks designed for roadside use and compliant with applicable regulations.

Long-term use

For semi-permanent or long-term installations, concrete barriers resist vandalism, weather damage and daily wear and tear.

The safety barriers are connected together at the scarf joint by M24 high tensile bolts.

TVCBs are always available direct from stock for nationwide next day delivery.

Delivery options on various vehicle options available, along with a crane off-load and place service

Temporary Vertical Concrete Barriers

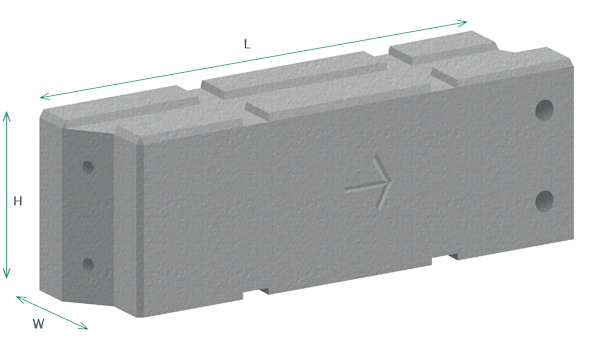

Units are connected together at the scarf joint, using M24 diameter high-tensile bolts. Units can also be fixed to the carriageway if required, by use of anchor plates bolted to the underside of the barriers.

For more information call 01952 588 885

Important note:

It is the customer’s responsibility to ensure appropriate structural checks are carried out before any precast concrete products are installed.

TVCB’s should only be lifted/off-loaded from above using the central 5 tonne pin anchor and clutch or the four M24 threaded sockets and lifting loops.

Prior to lifting older / pre-used blocks check the lifting pin for wear / corrosion and check the block for cracks. If the block is cracked or the pin is worn it could fail when being lifted.