Legato® Interlocking Concrete Blocks

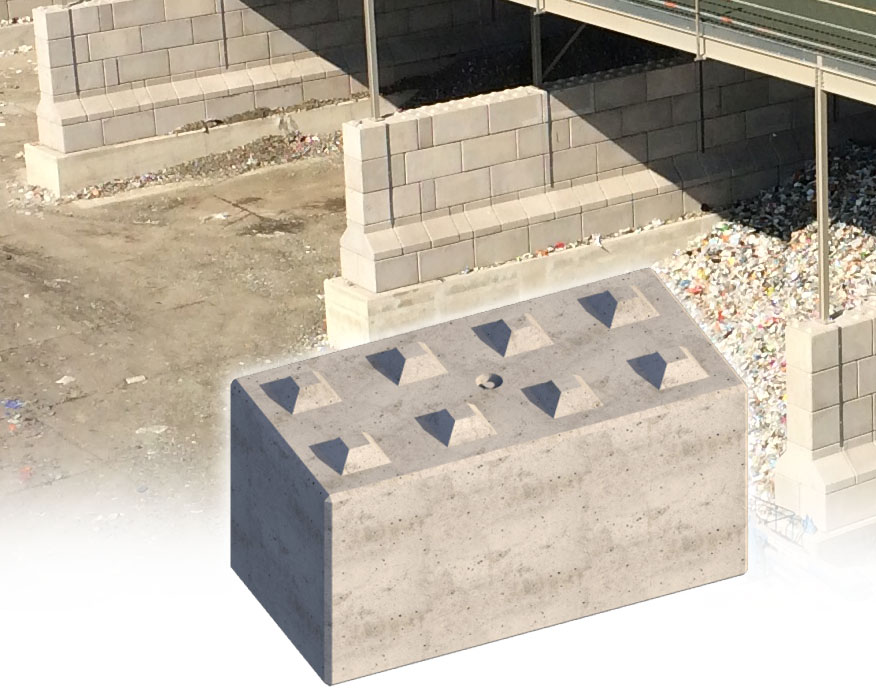

Legato® walling is made high strength engineered blocks that are manufactured from concrete, without any recycled or synthetic materials, meaning they offer the ultimate engineered interlocking concrete block.

Legato® blocks offer versatile solutions for numerous applications, including:

- Blast walls

- Bridge abutments and supports

- Coastal erosion

- Counterweights and kentledge

- Farm security and buildings

- Fire break walls

- Flood defence walls

- Industrial buildings

- Material storage bays – including aggregates, grain, salt, scrap metals, wood chip, white goods, waste)

- Network Rail – any line open (ALO) and track walling

- Pendine walls

- Public sector projects

- Retaining walls

- Silage clamps

- Temporary works

Legato® concrete blocks are derived from the Italian word, Legato, meaning “tied together”.

Why use Legato® concrete blocks?

- High strength: manufactured using 50N/mm² concrete, the highest in Europe for interlocking blocks.

- Durability: we offer extreme levels of durability due to high-strength concrete composition combined with the lack of steel reinforcement or recycled aggregates.

- Environment: Our production processes are state-of-the-art, with products made in modern factories with efficient low energy methodologies. We minimise our carbon footprint in all areas, including the best use of the transport networks and thus reducing road miles.

- Flexibility: Each block features a cast-in lifting pin for easy loading and installation without the need for specialist lifting equipment.

- Quality: You can be assured that all raw materials are fully traceable and that our products are checked for dimensional accuracy, density and compressive strength on a regular basis.

- Quick installation: Standard block cover 1.28m² of wall area.

- Long-lasting: Made with high-quality, locally sourced aggregates and Portland cement.

- Fire Resistant: The blocks are Class A1 Fire Resistant, so can be used as part of your FPP (Fire Prevention Plan) and are recommended for use by many insurance companies as fire breaks.

- Compliance: Meets BS EN 1992-1-2004 standard for concrete structure design.

- Price: Our low-cost base and market leading efficient manufacturing processes enable us to provide you the most competitively priced blocks available.

- Service: By keeping large stocks, we are able to offer fast deliveries on different vehicles, including artics or rigids with or without crane offload facilities.

- Sustainability: Our blocks are made from 100% natural materials sourced from local quarries and are 100% recyclable at their end of life. This combined with a 120-year design-life is sure to help with your sustainability goals.

Before you start using any concrete blocks, we recommend that you check out our unique stability and loadings directory, where you will find lots of guidance on wall heights, material storage and ground bearing/foundations etc.

We want you to make an informed choice, which is why we have added a number of great downloads to assist you in designing your project, this includes stockbay walls and inspecting existing walls.

For guidance on wall heights, material storage and ground bearing, please consult our stability and loadings directory.

IMPORTANT NOTE:

It is the customer’s responsibility to ensure appropriate structural checks are carried out before any precast concrete products are installed.

External storage bays built using our interlocking blocks are deemed as a temporary structure, and typically do not require planning consent to erect, as they are easy to dismantle and relocate as needed, although we recommend that you should always check with your local authority first.

Installing a temporary structure rather than a permanent one, can result in lower or zero business rates and are generally cheaper to build.

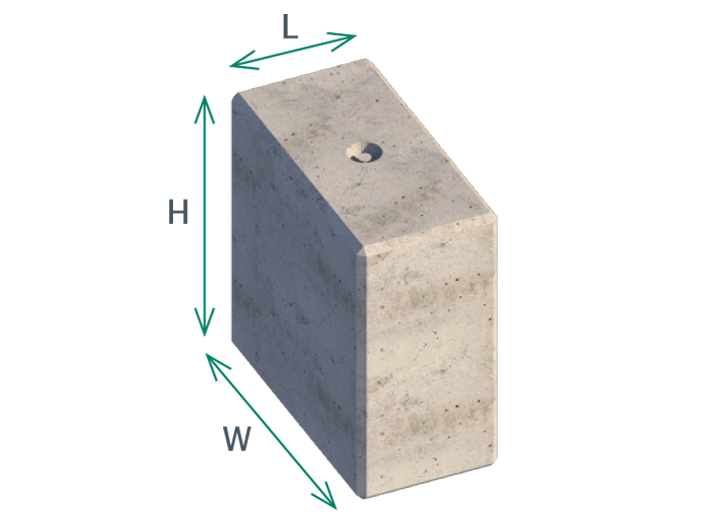

| Legato® Block Code |

Product Drawing | L x W x H (mm) | Weight |

| LG1 | 400 x 800 x 800 | 590kg | |

| LG2 | 400 x 800 x 800 | 600kg | |

| LG3 | 800 x 800 x 800 | 1180kg | |

| LG4 | 800 x 800 x 800 | 1200kg | |

| LG5 | 1200 x 800 x 800 | 1775kg | |

| LG6 | 1200 x 800 x 800 | 1800kg | |

| LG7 | 1600 x 800 x 800 | 2365kg | |

| LG8 | 1600 x 800 x 800 | 2400kg | |

| LG9 | 1600 x 800 x 800 | 1765kg | |

| LG10 | 1600 x 800 x 800 | 1800kg | |

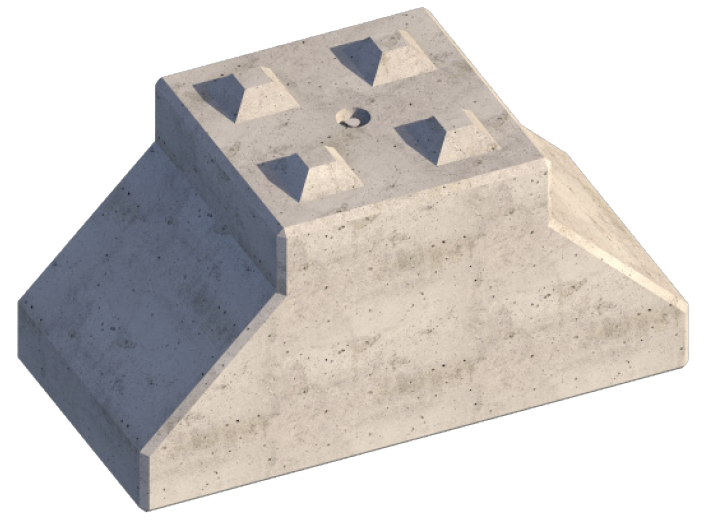

| LG11 (Spreader) | 1600 x 800 x 800 | 1800kg | |

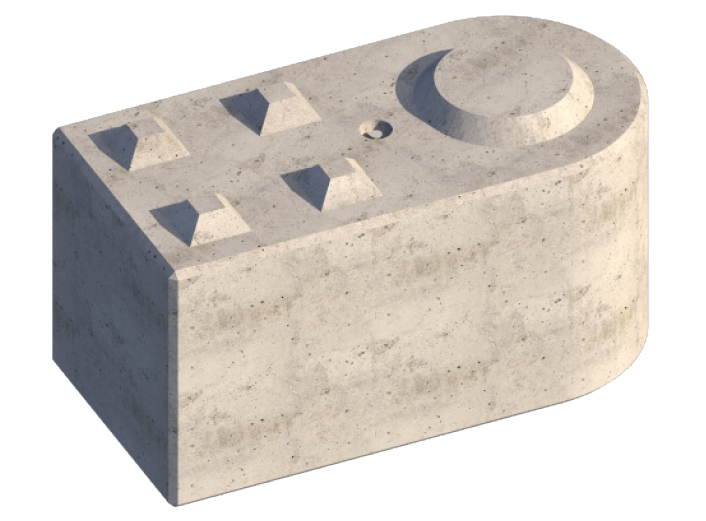

| LG12 (Bendi) | 1590 x 800 x 800 | 2240kg | |

| LG12F (Bendi) | 1590 x 800 x 800 | 2240kg | |

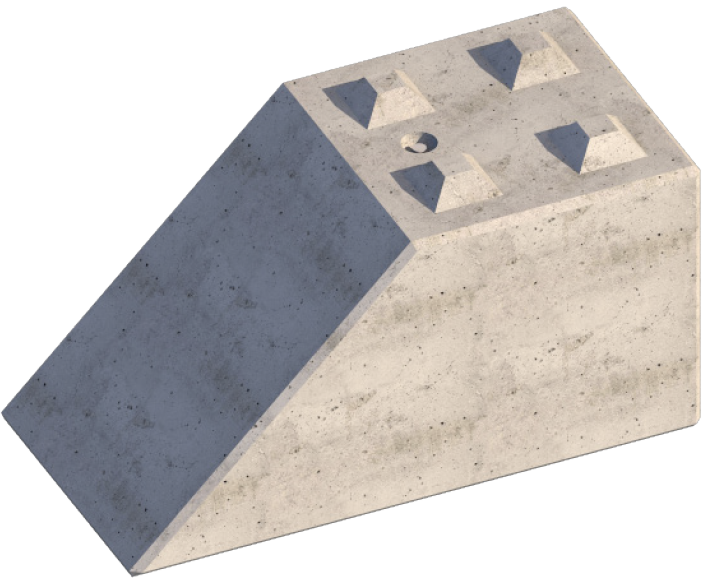

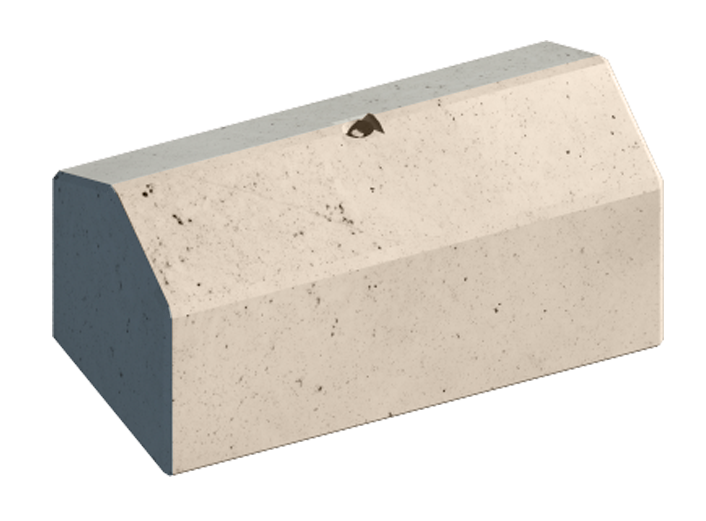

| LG14 (Capping) | 1600 x 800 x 800 | 2065kg | |

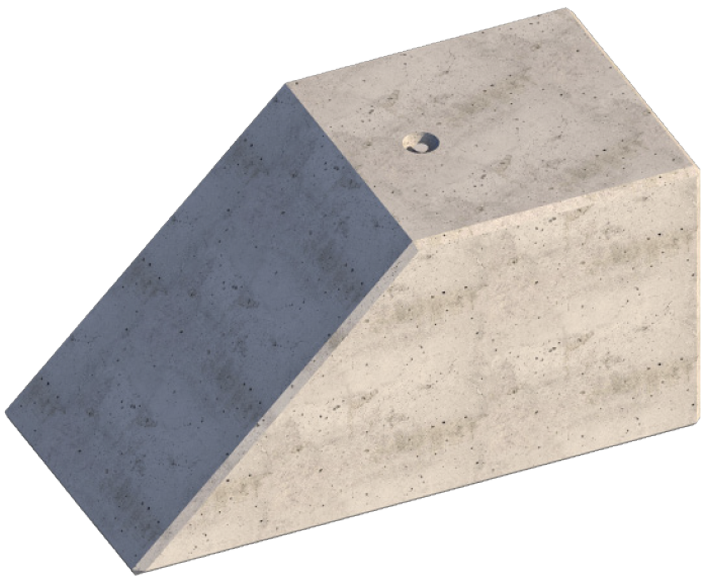

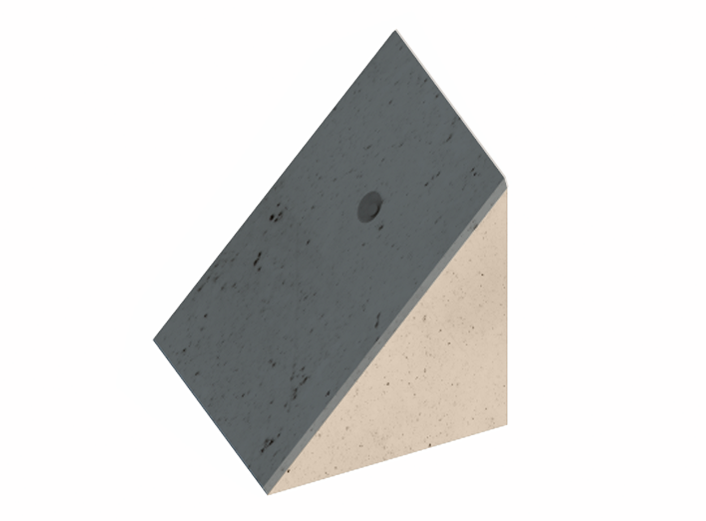

| LG WEDGE | 800 x 800 x 800 | 590kg |

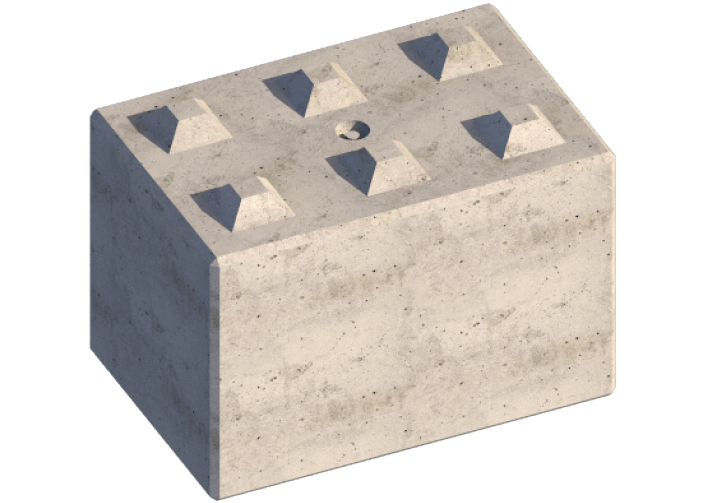

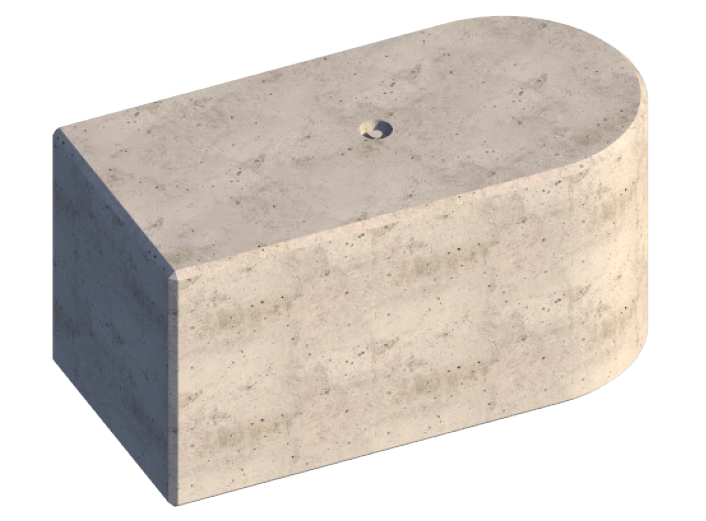

LG1

LG2

LG3

LG4

LG5

LG6

LG7

LG8

LG9

LG10

LG11 (Spreader)

LG12 (Bendi)

LG12F (Bendi)

LG14 (Capping)

LG Wedge

Legato® block showing 5 tonne lifting clutch

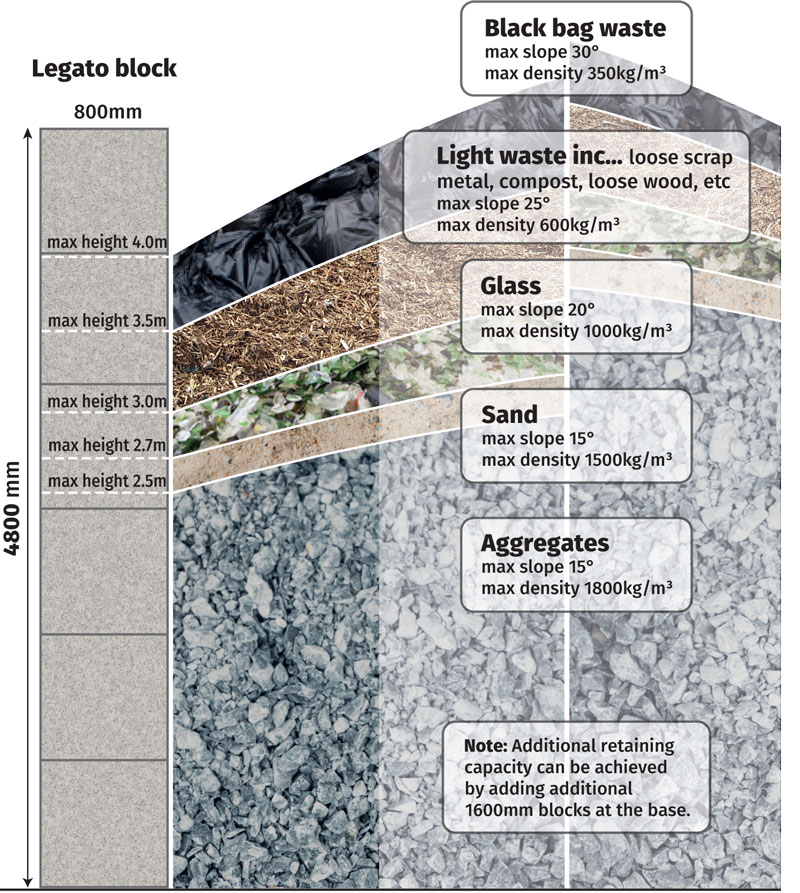

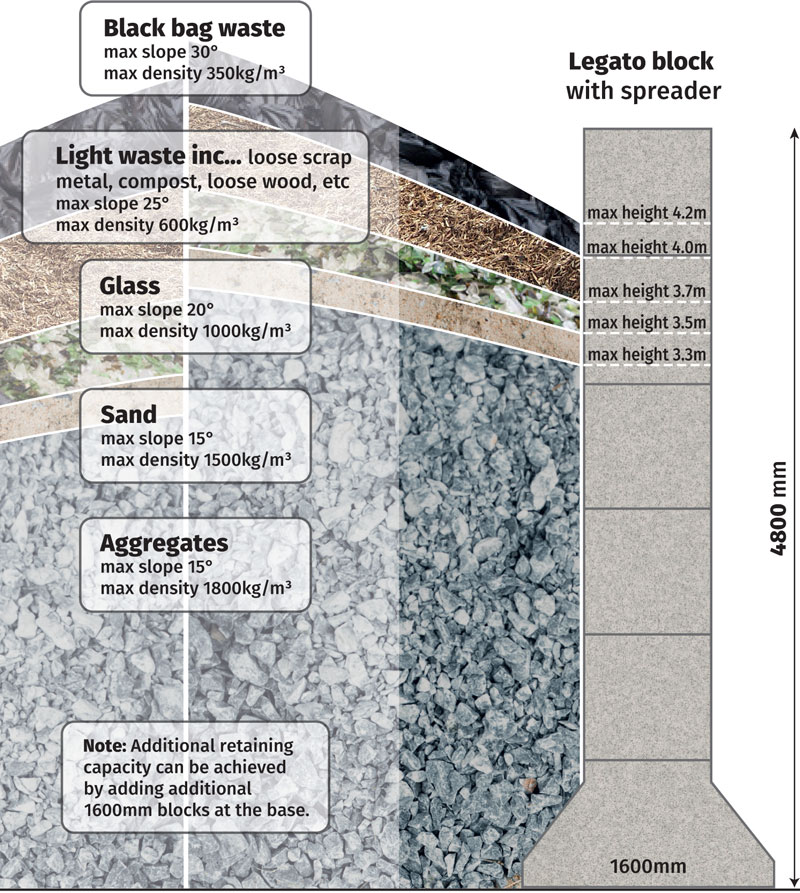

Typical loads… Legato® block walls

1. These loading figures are for guidance only – if in doubt consult a structural engineer.

2 The retained material should be allowed to naturally fall against the wall as it is stacked.

3 These loading tables relate to specific materials with a typical density and angle of repose, stacked to specific heights and slopes.

4 The client should ensure that the walls are built on a suitable base.

5 The density and angle of repose of each material shown are typical values only.

Important note – Prior to lifting older / pre-used blocks check the lifting pin for wear / corrosion and check the block for cracks.

If the block is cracked or the pin is worn it could fail when being lifted.

Additional Notes – Wind loading can affect the stability of single skin, stand-alone Legato block walls above 4.8m high. If in doubt get it checked by a qualified structural engineer. Direct impact between mobile plant and the block walls is unnecessary and should be avoided as in extreme cases this could dislodge blocks from the wall. If you identify a particular risk then strapping the top layers can help to mitigate the risk (see image below).

Legato blocks – top layers strapped

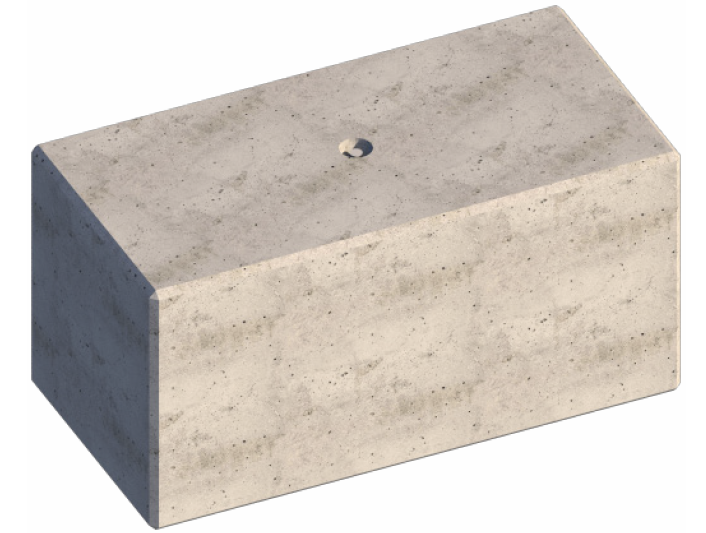

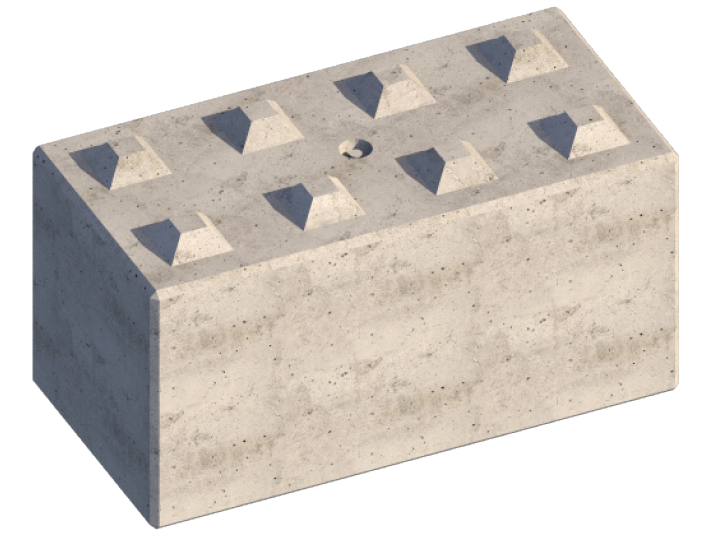

Please note the concrete finish of our interlocking blocks is classed as ‘Basic’ in accordance with the 4th Edition of the National Structural Concrete Specification for Building Construction. https://formworkdokauk.com/2019/08/12/a-guide-to-visual-and-architectural-concrete-finishes/ i.e. there are no requirements other than the concrete being adequately compacted to achieve the density and compressive strength required. The Legato blocks have a moulded face and a trowelled face – where appearance might be of concern, the moulded face tends to offer a smoother and more consistent look. Please note that blocks can be easily damaged if impact occurs during construction and Elite cannot be held responsible for damage caused after the blocks have been delivered and signed for by the client.

The Legato blocks have a moulded face and a trowelled face – where appearance might be of concern, the moulded face tends to offer a smoother and more consistent look. Please note that blocks can be easily damaged if impact occurs during construction and Elite cannot be held responsible for damage caused after the blocks have been delivered and signed for by the client.

If you require a decorative finish, please speak to our team to find out which will match your requirements on 01952 588885.