Gully Cover Slabs/Raisers

Manufacture in accordance with BS 5911 – 6, Gully Cover Slabs or Gully Risers are available in both square and ‘U’ shaped options, to give greater customer choice, for positioning next to kerb edges, with handling recesses for lifting brackets, to service the needs of those on-site.

Offering a cost-effective, yet stronger alternative to brickwork, along with durability, ease of installation and improved performance in surface water drainage systems, makes them the perfect choice for gully protection and creating a secure drainage system.

Benefits of concrete gully cover slabs

Quicker installation: Gully cover slabs are designed as seating for gully grates and are placed on top of 450mm gullies. They are faster to lay, resulting in reduced on-site labour costs.

Elimination of Weakspots: By using gully cover slabs, you eliminate brickwork vertical joints. These joints can be potential weakspots in the structure. Resulting in a more robust and stable solution.

Stability: Gully cover slabs offer greater stability compared to other materials. They ensure a secure seating for the gully grate, preventing movement or displacement.

No on-site brick laying: Instead of laying engineering bricks on-site, which can be time-consuming and labour-intensive, the precast concrete gully cover slab is a quality product, made within our factory in Shropshire.

Flush Fit: The concrete gully cover slab sits flush to the kerb, enhancing overall stability and ensuring a neat finish.

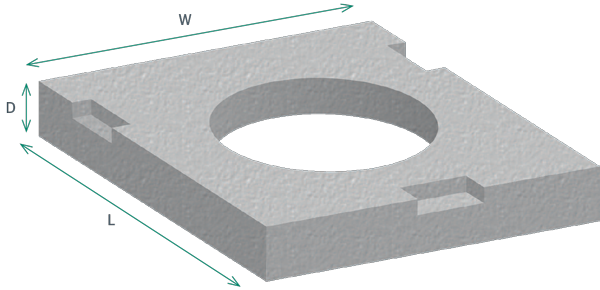

Square Gully Cover/Raisers

| Length | Width | Depth | Weight |

| Square | |||

| 750mm | 650mm | 100mm | 78kg |

| 750mm | 650mm | 65mm | 50kg |

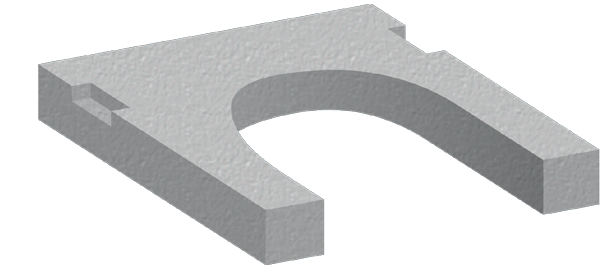

U-shape Gully Cover/Raisers

| Length | Width | Depth | Weight |

| U-shape | |||

| 585mm | 650mm | 100mm | 50kg |

| 585mm | 650mm | 65mm | 38kg |

Note: Appearance of a hairline crack in a seating ring or gully cover does not signify failure or a cause for rejection