Legato® interlocking concrete blocks for agricultural and farm applications

Legato® interlocking blocks provide an excellent solution for creating farm storage bays and other agricultural applications.

Our high strength interlocking concrete blocks offer versatility, durability and ease of installation, making them ideal for agricultural applications.

Benefits of Legato® blocks for farm storage

Quick installation

The interlocking design allows for rapid construction of storage bays, minimizing downtime on your farm.

Fire Resistant

The blocks are Class A1 Fire Resistant, so can be used as part of your FPP (Fire Prevention Plan) and are recommended for use by many insurance companies as fire breaks.

Compliance

Meets BS EN 1992-1-2004 standard for concrete structure design.

Adaptability

Easily reconfigured or relocated as your storage needs change.

Durability

Resistant to harsh weather conditions and heavy machinery use, common in an agricultural setting.

Load capacity

Can withstand significant material loads, please speak to our team to find out more.

Applications

Legato® walling is suitable for various farm storage applications, including:

- Grain storage

- Silage clamps

- Bulk material storage (aggregates, sand, compost etc)

- Waste and recycling storage

- Animal feed storage

Installation

Each Legato® block features an integral lifting pin, making the installation process simple and allowing for easy reconfiguration without specialised equipment. This feature is beneficial to farms and agricultural facilities that may need to adjust their storage layout seasonally or as needs alter.

By using Legato® walling for farm storage bays, you can create efficient, durable and flexible storage solutions that meet the diverse needs of modern agricultural operations.

Key features:

Strength

Manufactured for high-strength concrete, ensuring long-lasting performance.

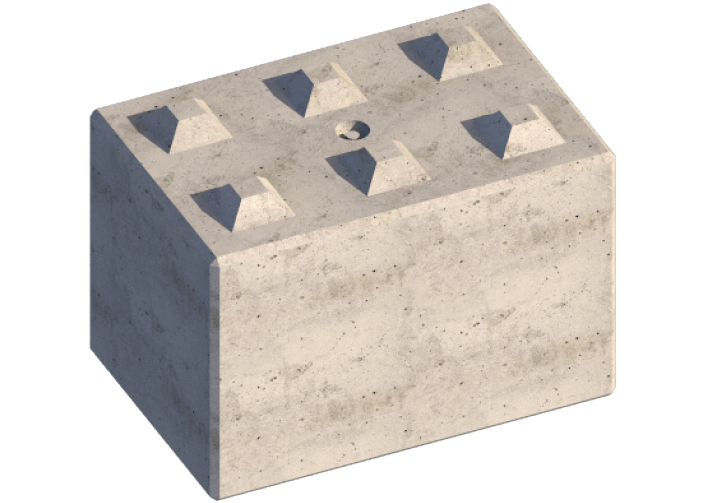

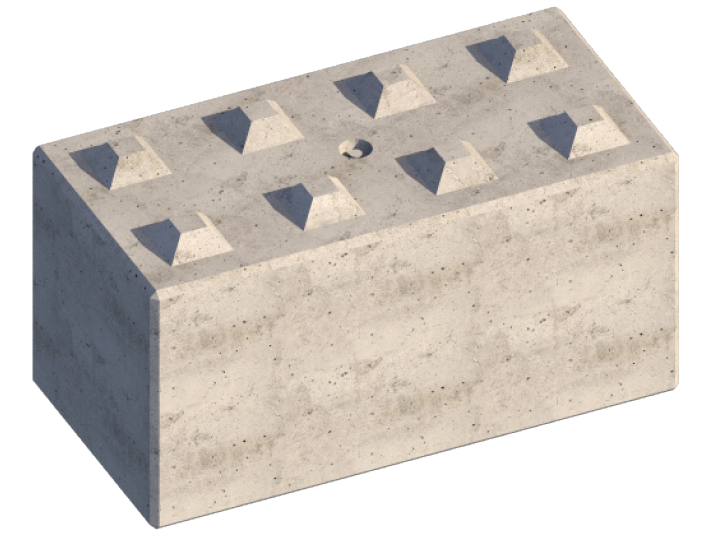

Interlocking Design

Blocks slot together, allowing for quick and easy assembly without the need for mortar or adhesives.

Versatility

Suitable for various farm storage needs, including grain, silage and bult materials.

Bespoke Options

Available in multiple sizes to accommodate different storage requirements.

We want you to make an informed choice, which is why we have added a number of great downloads to assist you in designing your project, this includes stockbay walls and inspecting existing walls.

For guidance on wall heights, material storage and ground bearing, please consult our stability and loadings directory.

IMPORTANT NOTE:

It is the customer’s responsibility to ensure appropriate structural checks are carried out before any precast concrete products are installed.

External storage bays built using our interlocking blocks are deemed as a temporary structure, and typically do not require planning consent to erect, as they are easy to dismantle and relocate as needed, although we recommend that you should always check with your local authority first.

Installing a temporary structure rather than a permanent one, can result in lower or zero business rates and are generally cheaper to build.

| Legato® Block Code |

Product Drawing | L x W x H (mm) | Weight |

| LG1 | 400 x 800 x 800 | 590kg | |

| LG2 | 400 x 800 x 800 | 600kg | |

| LG3 | 800 x 800 x 800 | 1180kg | |

| LG4 | 800 x 800 x 800 | 1200kg | |

| LG5 | 1200 x 800 x 800 | 1775kg | |

| LG6 | 1200 x 800 x 800 | 1800kg | |

| LG7 | 1600 x 800 x 800 | 2365kg | |

| LG8 | 1600 x 800 x 800 | 2400kg | |

| LG9 | 1600 x 800 x 800 | 1765kg | |

| LG10 | 1600 x 800 x 800 | 1800kg | |

| LG11 (Spreader) | 1600 x 800 x 800 | 1800kg | |

| LG12 (Bendi) | 1590 x 800 x 800 | 2240kg | |

| LG12F (Bendi) | 1590 x 800 x 800 | 2240kg | |

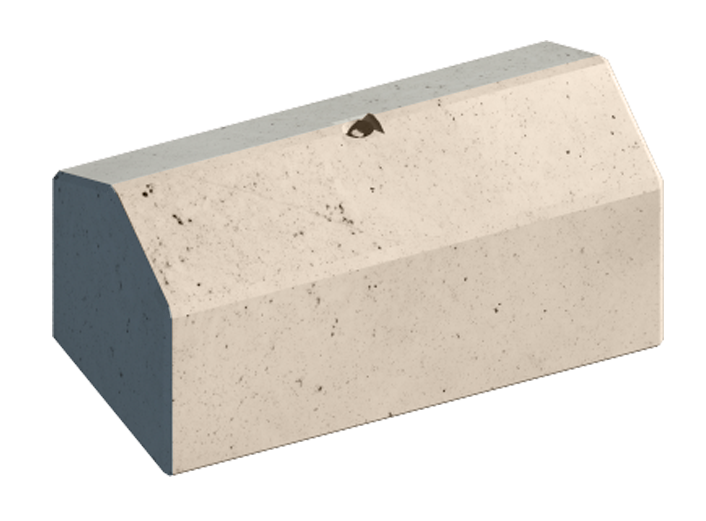

| LG14 (Capping) | 1600 x 800 x 800 | 2065kg | |

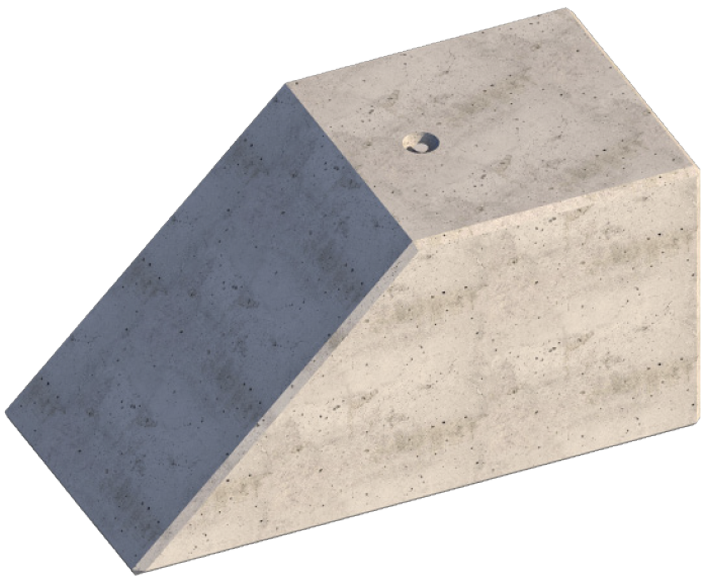

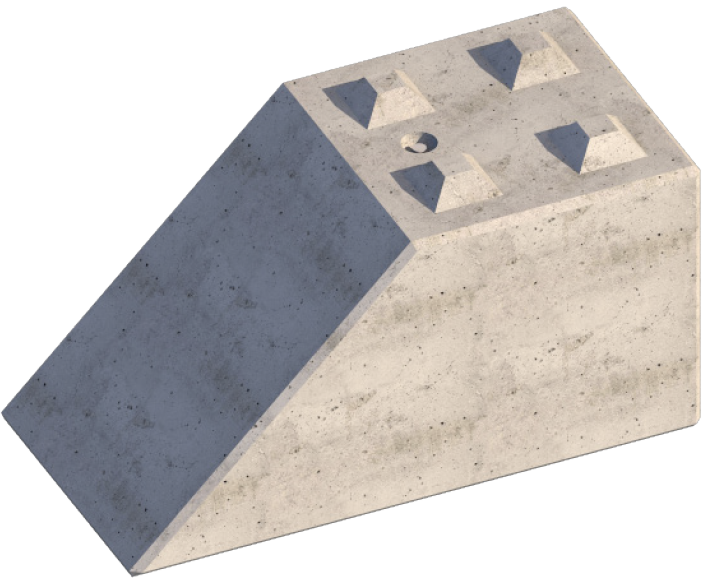

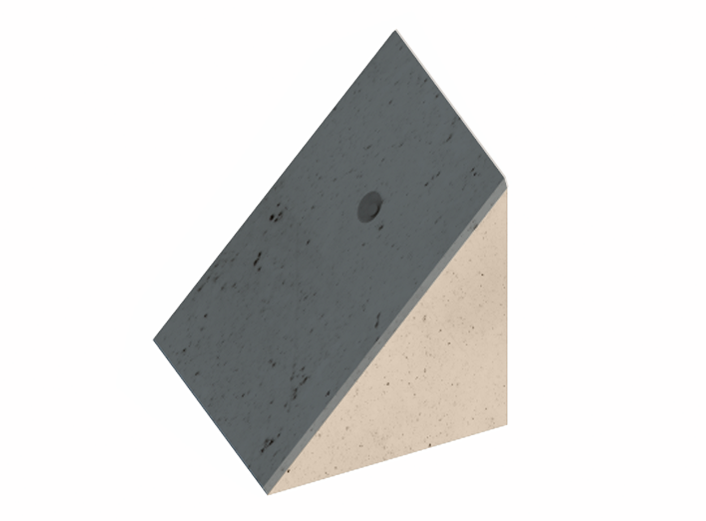

| LG WEDGE | 800 x 800 x 800 | 590kg |

LG1

LG2

LG3

LG4

LG5

LG6

LG7

LG8

LG9

LG10

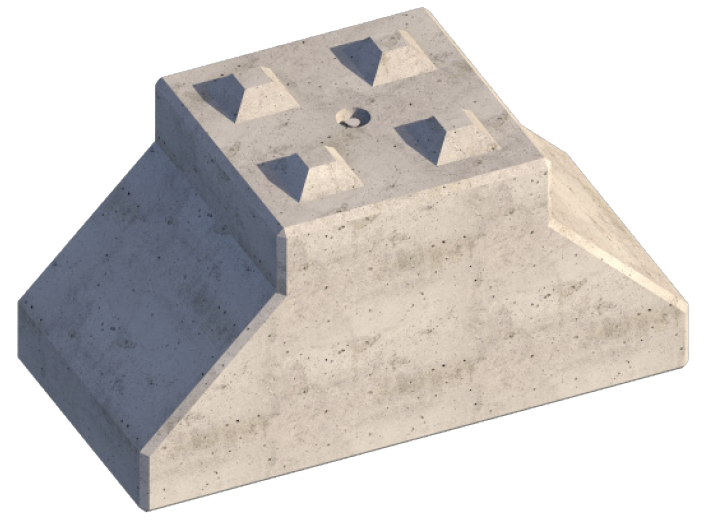

LG11 (Spreader)

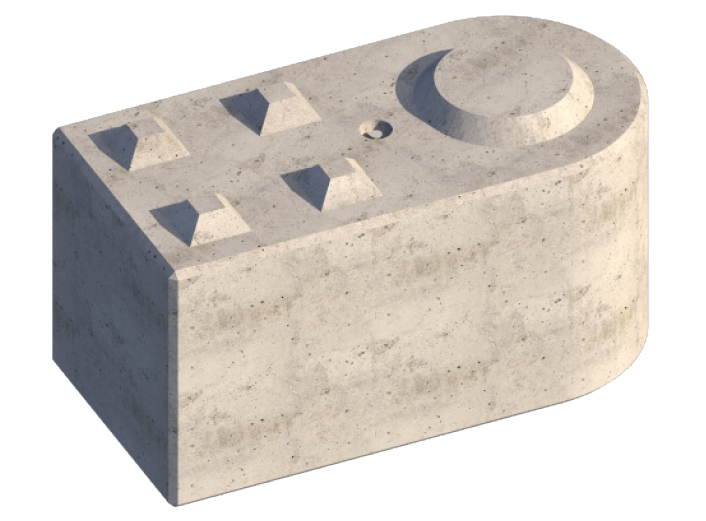

LG12 (Bendi)

LG12F (Bendi)

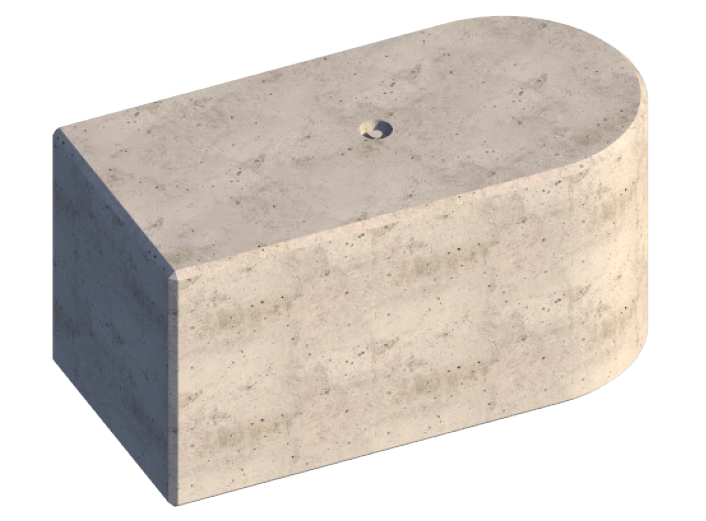

LG14 (Capping)

LG Wedge

Legato® block showing 5 tonne lifting clutch

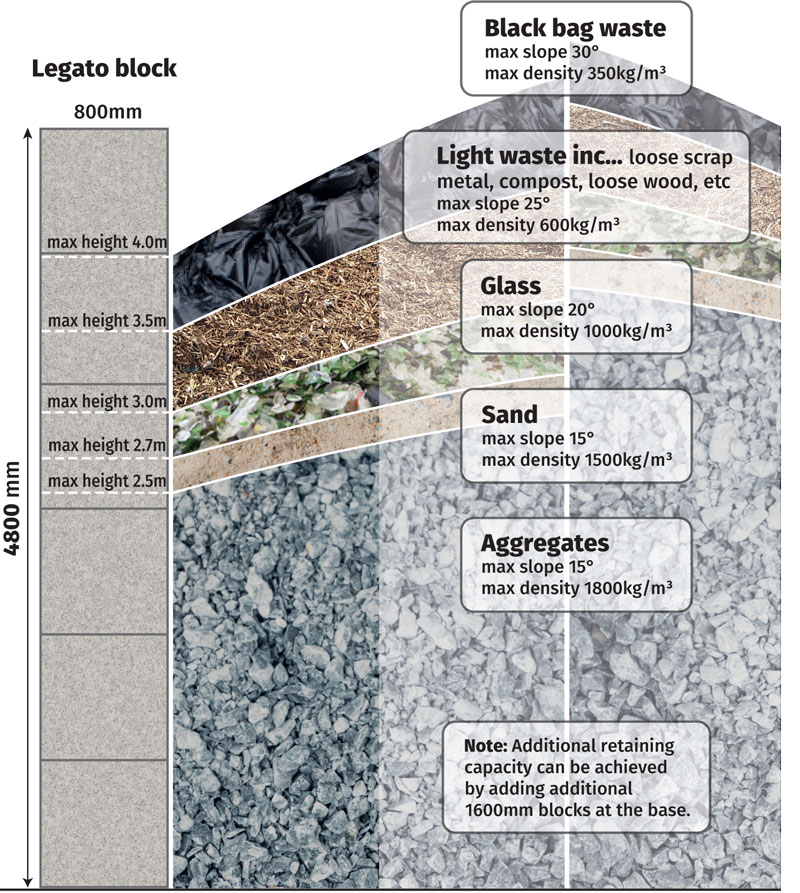

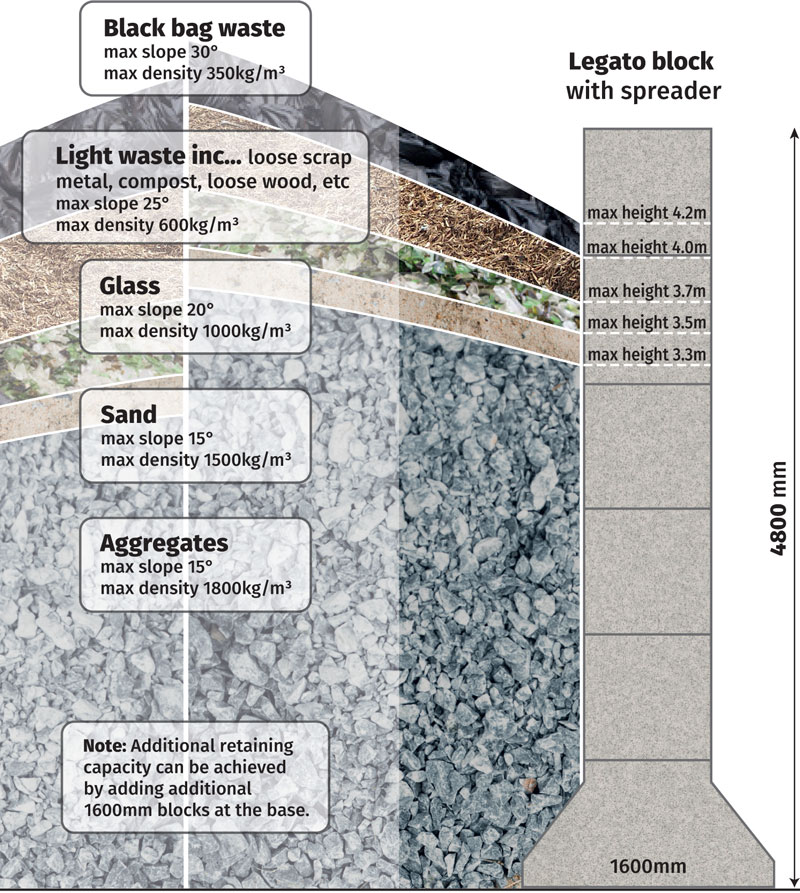

Typical loads… Legato® block walls

1. These loading figures are for guidance only – if in doubt consult a structural engineer.

2 The retained material should be allowed to naturally fall against the wall as it is stacked.

3 These loading tables relate to specific materials with a typical density and angle of repose, stacked to specific heights and slopes.

4 The client should ensure that the walls are built on a suitable base.

5 The density and angle of repose of each material shown are typical values only.

Important note – Prior to lifting older / pre-used blocks check the lifting pin for wear / corrosion and check the block for cracks.

If the block is cracked or the pin is worn it could fail when being lifted.

Additional Notes – Wind loading can affect the stability of single skin, stand-alone Legato block walls above 4.8m high. If in doubt get it checked by a qualified structural engineer. Direct impact between mobile plant and the block walls is unnecessary and should be avoided as in extreme cases this could dislodge blocks from the wall. If you identify a particular risk then strapping the top layers can help to mitigate the risk (see image below).

Legato blocks – top layers strapped

Please note the concrete finish of our interlocking blocks is classed as ‘Basic’ in accordance with the 4th Edition of the National Structural Concrete Specification for Building Construction. https://formworkdokauk.com/2019/08/12/a-guide-to-visual-and-architectural-concrete-finishes/ i.e. there are no requirements other than the concrete being adequately compacted to achieve the density and compressive strength required. The Legato blocks have a moulded face and a trowelled face – where appearance might be of concern, the moulded face tends to offer a smoother and more consistent look. Please note that blocks can be easily damaged if impact occurs during construction and Elite cannot be held responsible for damage caused after the blocks have been delivered and signed for by the client.

The Legato blocks have a moulded face and a trowelled face – where appearance might be of concern, the moulded face tends to offer a smoother and more consistent look. Please note that blocks can be easily damaged if impact occurs during construction and Elite cannot be held responsible for damage caused after the blocks have been delivered and signed for by the client.

If you require a decorative finish, please speak to our team to find out which will match your requirements on 01952 588885.